random user submitted photo

Working with canopy bows

8 posts

• Page 1 of 1

Working with canopy bows

My windscreen is in, but I'll soon be starting on the canopy. I bought the pre-bent canopy bows. Any hints on working with the pre-bent bows, since they don't match up with the fuselage contours? Like how to tweak and bend them and get a good match? I'm hoping I don't need to make a full bending pattern on my workbench.

Thanks,

Mike Smith

Sonex #439

Thanks,

Mike Smith

Sonex #439

Mike Smith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

- mike.smith

- Posts: 1413

- Joined: Tue Jan 29, 2013 8:45 pm

Re: Working with canopy bows

Mike,

I made a bending jig. I took a block of wood a little thicker than the bow and cut a big outside radius in it. Probably about a 8 or 10" radius. I then screwed a piece of 2x4 about 6" long just far enough away from the radius block to fit the bow in between them. You then put the bow in there and either push or pull it a little to change the radius. I saw the technique on someones sonex website before. It was either Jeff Schultz or Bob Milka. Just be carfull to keep the bow flat against the table when making the adjustments otherwise you get a twist as well as a bend. Also, small changes at the center of the bow has a large affect on the bottom ends of the bow. I found it easiest to start in the center of the bow and work down each side. I tried starting on one side and working my way up and over and it just made the bow a mess. My bows were pretty close but seemed to have two flat spots with no curve towards the bottom. Hope that helps. Good luck.

Keith

#554

I made a bending jig. I took a block of wood a little thicker than the bow and cut a big outside radius in it. Probably about a 8 or 10" radius. I then screwed a piece of 2x4 about 6" long just far enough away from the radius block to fit the bow in between them. You then put the bow in there and either push or pull it a little to change the radius. I saw the technique on someones sonex website before. It was either Jeff Schultz or Bob Milka. Just be carfull to keep the bow flat against the table when making the adjustments otherwise you get a twist as well as a bend. Also, small changes at the center of the bow has a large affect on the bottom ends of the bow. I found it easiest to start in the center of the bow and work down each side. I tried starting on one side and working my way up and over and it just made the bow a mess. My bows were pretty close but seemed to have two flat spots with no curve towards the bottom. Hope that helps. Good luck.

Keith

#554

- kmacht

- Posts: 758

- Joined: Tue Jun 21, 2011 11:30 am

Re: Working with canopy bows

You'll find the plans offer and "X/Y" coordinate pattern to fine-bend the bows (at least they used to). The problem is that it's for an airplane that does not really exist. You want the bows to fit your airplane. I suggest getting two large pieces of paper and, similar to taking a pencil to a penny to create an image, make an "image" of your front windshield and turtledeck arcs. Then, you are at least working with the exact shapes you'll use. I found that the bows can be bent using one's knee when bending in and the floor itself when bending out. I just made my second canopy and the bows took about 30 minutes each of trial and error bending to where I was happy with the shape...:)

Kip

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1050 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

2010 Waiex 0082 (first flight May 2010)

Jabiru 3300 #1637 and #3035

Dynon D-180

Becker radios

Garmin GDL 82 ADS-B

1050 hours

48 states visited

Based near Atlanta

Also flying a...

2000 Kolb Firestar II, Rotax 503, 575 hours

- N111YX

- Posts: 705

- Joined: Fri Jun 03, 2011 9:43 am

- Location: Atlanta, GA USA

Re: Working with canopy bows

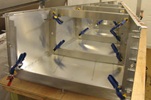

Here is a photo of a simple bending jig made with some scrap pieces of wood:

https://s3.amazonaws.com/expercraft/dal ... 2eca95.jpg

Other ideas presented here work well. There are a lot of ways to skin this cat ...

Dale

N319WF

https://s3.amazonaws.com/expercraft/dal ... 2eca95.jpg

Other ideas presented here work well. There are a lot of ways to skin this cat ...

Dale

N319WF

-

daleandee - Posts: 810

- Joined: Fri Feb 01, 2013 6:14 pm

Re: Working with canopy bows

So it sounds like making a jig to match the actual fuselage curves is not necessary. It sounds like the important thing is to have something between which to bend the bows in a flat manner.

Mike

Mike

Mike Smith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

- mike.smith

- Posts: 1413

- Joined: Tue Jan 29, 2013 8:45 pm

Re: Working with canopy bows

N111YX wrote:I found that the bows can be bent using one's knee when bending in and the floor itself when bending out. I just made my second canopy and the bows took about 30 minutes each of trial and error bending to where I was happy with the shape...:)

30 min each? wow Kip.. want to come over and do mine for me ;)

I am at this phase.. been struggling with the canopy bows for two days now. I ended up buying this tubing roller from Harbor Freight, thinking it would make the job a bit easier..

http://www.harborfreight.com/tubing-roller-99736.html

and they sell after market dies in all shapes and sizes for the roller here

http://www.swagoffroad.com/Harbor-Freig ... _p_51.html

Its a fine tool for making the initial bend (if you were starting from scratch, with a straight piece of tube), but not the right tool for this job to make the tight tweaks to the bow to get it to conform to the exact shape you need it to be in.

I'll give it another shot trying my knees..

Waiex # 142 - Taildragger, Jabiru 3300

First Flight - July 13th, 2015

450 hours and counting..

First Flight - July 13th, 2015

450 hours and counting..

-

142YX - Posts: 263

- Joined: Thu Sep 01, 2011 10:18 pm

Re: Working with canopy bows

Check out this entry on Eric Witherspoon's kitlog:

http://www.mykitlog.com/users/display_l ... 473&row=31

seems like an easy set-up to bend/adjust the bows.

http://www.mykitlog.com/users/display_l ... 473&row=31

seems like an easy set-up to bend/adjust the bows.

Michael

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

Sonex #145 from scratch (mostly)

Taildragger, 2.4L VW engine, AeroInjector, Prince 54x48 P-Tip

VH-MND, CofA issued 2nd of November 2015

First flight 7th of November 2015

Phase I Completed, 11th of February 2016

http://www.mykitlog.com/rizzz/

- rizzz

- Posts: 869

- Joined: Tue Jun 21, 2011 2:07 am

- Location: Wollongong, NSW, Australia

Re: Working with canopy bows

Hi,

Just finished the canopy frame last night. In the end my knee:

http://www.mykitlog.com/users/display_l ... 0607&row=6

And a couple of 2x4's did just fine:

http://www.mykitlog.com/users/display_l ... 0649&row=5

Mike Smith

#439

Just finished the canopy frame last night. In the end my knee:

http://www.mykitlog.com/users/display_l ... 0607&row=6

And a couple of 2x4's did just fine:

http://www.mykitlog.com/users/display_l ... 0649&row=5

Mike Smith

#439

Mike Smith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

Sonex N439M

Scratch built, AeroVee, Dual stick, Tail dragger

http://www.mykitlog.com/mikesmith

- mike.smith

- Posts: 1413

- Joined: Tue Jan 29, 2013 8:45 pm

8 posts

• Page 1 of 1

Who is online

Users browsing this forum: No registered users and 52 guests