random user submitted photo

Cooling your AeroVee Heads

Re: Cooling your AeroVee Heads

Many ‘Oshes’ ago I attended an engine cooling forum held by the late Tony Bingelis. Among others he stressed three important points.

1)

Engine air cooling is by convection- and only to a very small degree by radiation. This means that cooling air not in direct contact with engine metal/cooling fins, does not cool anything at all.

2)

Cooling air inlet area openings are a function of engine power.

Cooling air outlet size areas are a function of airspeed. Very slow airplanes should have an inlet/outlet size with a ratio of about 1:3 (outlet area is three times the size of inlet area). On the really fast movers this relation could be brought back to 1:1.5

3)

Cooling air can’t be pressed into the cowling- it must be sucked in by the vacuum created in the outlet area. This means you need to dump your cooling air in a low pressure area created by the cowling.

1)

Engine air cooling is by convection- and only to a very small degree by radiation. This means that cooling air not in direct contact with engine metal/cooling fins, does not cool anything at all.

2)

Cooling air inlet area openings are a function of engine power.

Cooling air outlet size areas are a function of airspeed. Very slow airplanes should have an inlet/outlet size with a ratio of about 1:3 (outlet area is three times the size of inlet area). On the really fast movers this relation could be brought back to 1:1.5

3)

Cooling air can’t be pressed into the cowling- it must be sucked in by the vacuum created in the outlet area. This means you need to dump your cooling air in a low pressure area created by the cowling.

Last edited by Kai on Sun Oct 17, 2021 11:57 am, edited 2 times in total.

- Kai

- Posts: 240

- Joined: Wed Jul 30, 2014 1:36 am

Re: Cooling your AeroVee Heads

"Your heads will cool much more effectively if they look like the ones on the right of this photo."

I'm not sure this is a correct statement. It may need some kind of analysis. It may be taking available air from the fins. Engineers like to think of problems, or solutions, as limits. If we open up even more area for air to go thru, it reduces the air going through the fins. Think of the path of least resistance. We really want nice clean flow paths between the fins and as much of the available air as possible going thru there.

I'm not sure this is a correct statement. It may need some kind of analysis. It may be taking available air from the fins. Engineers like to think of problems, or solutions, as limits. If we open up even more area for air to go thru, it reduces the air going through the fins. Think of the path of least resistance. We really want nice clean flow paths between the fins and as much of the available air as possible going thru there.

- Scott Todd

- Posts: 359

- Joined: Mon Jun 24, 2019 7:40 pm

- Location: Chandler, AZ

Re: Cooling your AeroVee Heads

Kai wrote:Many ‘Oshes’ ago I attended an engine cooling forum held by the late Tony Bingelis. Among others he stressed three important points….

3)

Cooling air can’t be pressed into the cowling- it must be sucked in by the vacuum created in the outlet area. This means you need to dump your cooling air in a low pressure area created by the cowling.

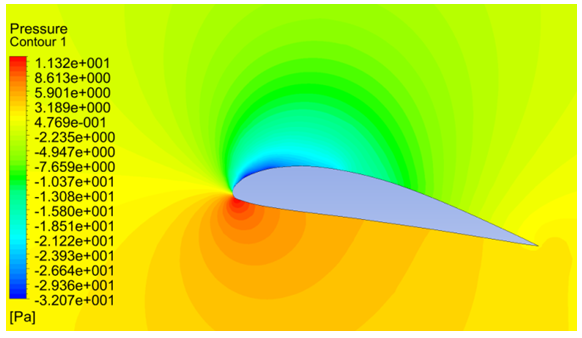

The above issue is why the side exits of the “B” model cowl work so well, compared to the original bottom exit. The Sonex fuselage is roughly airfoil/shaped, and if you’ve ever looked at the pressure distribution around an airfoil in a slight climb you’ll see there’s a region of high pressure near the bottom cowling exits:

This is why most legacy Sonex/Waiex builders have put a “lip”/deflector at the leading edge of the bottom cowl exits. The deflector disrupts the high-pressure airflow along the underside of the cowl and creates a low-pressure zone behind it, helping to pull hot air out of the cowling (at the cost of a bit of added drag). Jeff Shultz’s site has a good image of what this lip/deflector looks like:

—Noel

- NWade

- Posts: 527

- Joined: Mon Aug 08, 2011 3:58 pm

Re: Cooling your AeroVee Heads

That's good NWade. Since I studied Aerodynamics in college, I've asked for nearly 40 years why exits are on the bottom. I think it was always aesthetics. Sonex did a good job on them on the B model. It was the first thing I noticed the first time I saw one.

I think Tony's explanation is slightly skewed to help reach a more divers audience. In theory its the difference between Total and Static pressure. This is defined as Dynamic pressure which is usually associated with velocity. But in our basic engine cowls, its all about the pressure differential forcing the air thru the head fins. This is why its important to seal the upper baffles. We need to build up that pressure to force the air thru the fins. There are a few good research papers on cooling GA airplane engines.

For future readers, it ALWAYS comes down to sealed upper baffles, clean air thru the fins, and LOTS of exit area to pull, extract, or whatever you want to call it, the hot air out. It seem so simple yet so many people just miss the point :)

I think Tony's explanation is slightly skewed to help reach a more divers audience. In theory its the difference between Total and Static pressure. This is defined as Dynamic pressure which is usually associated with velocity. But in our basic engine cowls, its all about the pressure differential forcing the air thru the head fins. This is why its important to seal the upper baffles. We need to build up that pressure to force the air thru the fins. There are a few good research papers on cooling GA airplane engines.

For future readers, it ALWAYS comes down to sealed upper baffles, clean air thru the fins, and LOTS of exit area to pull, extract, or whatever you want to call it, the hot air out. It seem so simple yet so many people just miss the point :)

- Scott Todd

- Posts: 359

- Joined: Mon Jun 24, 2019 7:40 pm

- Location: Chandler, AZ

Re: Cooling your AeroVee Heads

Scott- I can offer no argument!

Slightly bothered by the Sonex Legacy cowling shape when operating #0525 with the aircooled Jab and associated high cht’s, I decided to branch out on my own when converting to a R912ULS. In my mind the cowling issue was mainly that the bottom of the cowling was a continuous curvature: the higher the angle of attack, the poorer the cooling capacity- lips or no lips!

So i went for a slightly deeper bottom cowling design. This made possible a flat section in front of and in the same plane as the bottom front alu sheet of the fuselage, and this is where I positioned the cooling air outlet channels, using as much of the cowling width as possible. In addition the side outlets were built into the cowling.

The result can be seen in the photo: and now the thing cools like there is no tomorrow!

Slightly bothered by the Sonex Legacy cowling shape when operating #0525 with the aircooled Jab and associated high cht’s, I decided to branch out on my own when converting to a R912ULS. In my mind the cowling issue was mainly that the bottom of the cowling was a continuous curvature: the higher the angle of attack, the poorer the cooling capacity- lips or no lips!

So i went for a slightly deeper bottom cowling design. This made possible a flat section in front of and in the same plane as the bottom front alu sheet of the fuselage, and this is where I positioned the cooling air outlet channels, using as much of the cowling width as possible. In addition the side outlets were built into the cowling.

The result can be seen in the photo: and now the thing cools like there is no tomorrow!

Last edited by Kai on Mon Oct 18, 2021 4:14 pm, edited 1 time in total.

- Kai

- Posts: 240

- Joined: Wed Jul 30, 2014 1:36 am

Re: Cooling your AeroVee Heads

NWade wrote:This is why most legacy Sonex/Waiex builders have put a “lip”/deflector at the leading edge of the bottom cowl exits. The deflector disrupts the high-pressure airflow along the underside of the cowl and creates a low-pressure zone behind it,

That lip is vital at high angles of attack. Without the lip the exit slot is exposed to the airflow and actually pressurizes the output side of the cowl. That lip needs to be deep enough to maintain a vacuum when the plane is pitched steely up - like in a Vx climb.

Graeme JW Smith

-

GraemeSmith - Posts: 939

- Joined: Sat May 18, 2019 8:58 am

- Location: RI

Re: Cooling your AeroVee Heads

Scott Todd wrote:I thought it would have been higher. 1/2" is a long way in :) But it helps to illustrate the point to other curious builders. Just put it where Sonex recommends and go from there.

After read-out of the highest temp measured it showed 268 degrees C > 515 Fahrenheit. So it was indeed higher at some point.

- AlexZ

- Posts: 46

- Joined: Fri May 27, 2016 8:06 am

Re: Cooling your AeroVee Heads

Does anyone know what the approx differential pressure should be between the pressure plenum above the engine to the low side below the engine? I'm going to measure this on mine and would like an idea of what is acceptable and not.

Turbo Aerovee, Sonex B cowl.

Peter

Turbo Aerovee, Sonex B cowl.

Peter

Peter Hoey

SEL Pvt, Comm Glider, CFIG, Pawnee & L19 Towpilot

Philadelphia Glider Council

Sonex B SNB0021, N561PH, Taildragger, Aerovee Turbo, MGL MX1, First flight Dec 18, 2022

Also built Sonerai IIL N86PH

SEL Pvt, Comm Glider, CFIG, Pawnee & L19 Towpilot

Philadelphia Glider Council

Sonex B SNB0021, N561PH, Taildragger, Aerovee Turbo, MGL MX1, First flight Dec 18, 2022

Also built Sonerai IIL N86PH

- pfhoeycfi

- Posts: 379

- Joined: Wed Jun 28, 2017 3:45 pm

Re: Cooling your AeroVee Heads

I don't know that I've ever seen it posted before.

Bryan Cotton

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

Poplar Grove, IL C77

Waiex 191 N191YX

Taildragger, Aerovee, acro ailerons

dual sticks with sport trainer controls

Prebuilt spars and machined angle kit

Year 2 flying and approaching 200 hours December 23

-

Bryan Cotton - Posts: 5110

- Joined: Mon Jul 01, 2013 9:54 pm

- Location: C77

Re: Cooling your AeroVee Heads

Bryan Cotton wrote:I don't know that I've ever seen it posted before.

Looking at the Jab 3300 manual. It has a very good section on cooling and checking the DP and suggests that the DP should be no lower 2.4 " wc at 1.3 Vs. Of course the Jab arrangement isn't the same as the Aerovee and the number might be something different. But I'm curious and will get measurements. Might buy a digital manometer...more tools.

I'm also wondering if a separate isolated air supply to the oil cooler using a NACA duct might help. Of course the air outlet of the cooler would need to be isolated and vented separately as well so as not to effect the cowl low side pressure. The air that was going to the cooler would then be available to the cylinders and heads. I'm sure someone has thought of this and tried it. Curious how it worked out.

peter

Peter Hoey

SEL Pvt, Comm Glider, CFIG, Pawnee & L19 Towpilot

Philadelphia Glider Council

Sonex B SNB0021, N561PH, Taildragger, Aerovee Turbo, MGL MX1, First flight Dec 18, 2022

Also built Sonerai IIL N86PH

SEL Pvt, Comm Glider, CFIG, Pawnee & L19 Towpilot

Philadelphia Glider Council

Sonex B SNB0021, N561PH, Taildragger, Aerovee Turbo, MGL MX1, First flight Dec 18, 2022

Also built Sonerai IIL N86PH

- pfhoeycfi

- Posts: 379

- Joined: Wed Jun 28, 2017 3:45 pm

Who is online

Users browsing this forum: No registered users and 24 guests